1. Basic concept of brushless motor

According to the structure and working principle of the motor, we can divide the motor into a brush motor, an internal rotor -free motor, and an external rotor -free motor.

There is a brush motor: We are also known as DC motors or carbon brushing motors. They are the oldest types of motor and the most current number of motor types. When the motor works, the coil and the directioner rotate, the magnetic steel and the carbon brush are not rotated, and the alternating changes in the direction of the coil current are completed by the conversioner and brush with the motor. This motor has the advantages of relatively low cost, high torque, simple structure, and easy maintenance.

However, due to structural restrictions, the shortcomings are also obvious:

1. The spark generated by the mechanical replacement causes wiper and brush friction, electromagnetic interference, large noise, and short life.

2. The structure is complicated, the reliability is poor, and the failure is large, and it needs to be maintained frequently.

3. Due to the existence of the directioner, the further decline of rotor inertia is limited, affecting dynamic performance.

Therefore, the model industry is mainly used in the slower and sensitive car models and ship models. The airline model rarely uses a brush motor.

Brushless Motor:This is the most used motor in the model industry except the brush motor. The brushless brush device that does not use the machine without a brush -free DC motor is used. The permanent magnet material used as a rotor as a rotor has great advantages in performance compared to ordinary traditional DC motors. It has the advantages of high efficiency, low energy consumption, low noise, long life, high reliability, servo control, and stepless frequency conversion speed adjustment. As for the disadvantages ... it is more expensive and difficult to maintain. , High -speed car models and boat molds.

However, a single brushless motor is not a complete power system. Basically, the brushless control must be continuously operated through the controller of the brushless controller, that is, the electrical control. Ordinary carbon brush motors rotate are winding, and the brushless motor is magnets in both the external rotor structure and the inner rotor structure rotation. So any motor is composed of stator and rotor.

The stator of the brushless motor is the part of the rotation magnetic field, which can support the rotor to rotate. It is mainly composed of silicon steel sheets, lacquer cables, bearing, and supporting parts; the rotor is pasted with iron boron magnets. The components are mainly composed of axis, magnets, and supporting parts. In addition, the number of magnetic poles composed of stator and rotor also affects the speed and torque of the motor.

Second, the structure of a brushless motor

The front cover, middle shell, and back cover of the brushless engine are the overall structural parts, which plays a role in building the overall structure of the motor. However, the housing of the outer rotor -free motor is also the magnetic pathway of the magnet, so the shell must be a magnetic material composition. The shell of the inner rotor is only a structural part, so the material is not limited. However, the inner rotor motor is one more rotor core than the external rotor motor. The effect of this rotor core also plays the role of a magnetic pathway.

magnet: magnetIt is an important part of the brushless motor installed on the rotor. Most of the performance parameters of the brushless motor are related to magnets, including power, speed, torque, etc.

Silicon steel sheet:There is an important part of a brushless motor. Of course, there is no silicon steel sheet without a brush -free motor, but most of the brushless motors are currently grooves. Its role in the entire system is mainly to reduce magnetic resistance and participate in magnetic circuit operations.

Turning axle:It is the direct force of the motor rotor. The hardness of the rotation shaft must meet the requirements of high -speed rotation of the rotor.

Bearing:It is the guarantee of the smooth operation of the motor. The bearings can be divided into sliding bearings and rolling bearings, and the rolling bearings can be subdivided into ten categories such as deep groove ball bearings, rolling needle bearings, and corner contact bearing. Use deep groove ball bearings.

Third, the working principle of DC brushless motor

DC brushless motor power system consists of three parts: rotor, stator, and position sensor.The location sensor is changed according to the change of the rotor position, and the current of the stator winding is replaced along a certain order (that is, detect the position of the rotor magnet pole relative stator winding, and generate the location sensing signal at the determined position. After the signal conversion circuit processing is processed Control the power switch circuit and switch the winding current according to a certain logical relationship). The working voltage of the stator winding is provided by the electronic switch circuit controlled by the position sensor output.

There are three types: magnetic sensitivity, photoelectric and electromagnetic.

The DC brushless motor of the magnetic position sensor, its magnetic sensing device (such as the Hall component, magneticist diode, magnetic sensitivity pipe, magnetic resistance or special integrated circuit, etc.) To detect the magnetic field changes produced during the permanent magnet and rotor rotation.

The DC brushless motor of the photoelectric position sensor is used to configure the photoelectric sensing device according to a certain position on the stator component. The rotor is equipped with a shading plate, and the light source is a light -emitting diode or a small light bulb. During the rotation of the rotor, due to the effect of the shading plate, the optical component on the stator will intermittently intermittent pulse signals at a certain frequency.

The brushless DC motor using the electromagnetic position sensor is an electromagnetic sensor component (such as a coupling transformer, a close switch, a LC resonance circuit, etc.) on the stator component. Generate a high -frequency regulation signal (the amplitude changes with the position of the rotor).

Simply put, the DC brushless motor rely on changing the current wave frequency frequency conversion and waveforms that change the input to the brush -free motor stator coil. A magnetic field that is fully turned around the motor geometric axis around the winding coil. This magnetic field drives the rotor on the rotor The permanent magnet magnetic steel rotates, and the motor rotates. The performance of the motor is related to factors such as the number of magnetic steel, the magnetic flux strength of the magnetic steel, and the voltage of the motor input. It is a DC power. The current requires the electronic speed regulator to turn it into a 3 -phase AC power. It also needs to receive the control signal from the remote control receiver to control the speed of the motor to meet the model use needs.

In general, the structure of the brushless motor is relatively simple. What really determines its use is still a brush -free electronic speed regulator (that is, electrical). The overall control of the processing process, so the price is generally much higher than the brushless motor.

First of all, give you a few foundations: the left hand rules, the right hand, the right hand, the right hand spiral. Don't be aggressive, I will explain it below.

The left -handed rules, this is the basis for the analysis of motor rotation force analysis. Simply put, it is the load conductor in the magnetic field, which will be effective.

Let the magnetic line pass through the front of the palm, the direction of the finger is the direction of the current, and the direction of the thumb is the direction of magnetic force. I believe that people who like to play models still have a certain physical foundation.

The right hand is determined. This is the basis for generating an electromotive force. The opposite of the left hand is contrary to the left hand. The conductor in the magnetic field generates electromotive force due to the trial traction and cutting magnetic line.

Let the magnetic line pass through the palm, the direction of the thumb is the direction of the movement, and the direction of the finger direction is the direction of the electric momentum. Why do you talk about biological electric momentum? I do n’t know if you have similar experiences, combine the three -phase line of the motor, and use your hand to rotate the motor to find that the resistance is very large. The current flow over the conductor will generate the opposite force of the rotation direction, and everyone will feel that there is a lot of resistance to rotation. If you don't believe it, try it.

Three -phase line is separated, the motor can easily rotate

The three -phase line merged, the motor rotation resistance is very large

The right hand spiral, hold the power screw wire tube with the right hand, so that the four -finger bending is consistent with the direction of the current. Then the end of the thumb is the N pole of the power screw tube.

This rule is the basis for judging the polarity of the wire. The direction of the red arrow is the direction of the current.

After reading the three major rules, let's take a look at the basic principles of motor rotation.

Part 1: DC motor model

We found a model of a DC motor that was physically physically, and a simple analysis was performed through magnetic circuit analysis.

State 1

When the coil on both ends is connected to the current, according to the screw of the right hand, the external plus magnetic induction intensity B (such as the direction of the rough arrow) will produce the direction of the direction. The direction of the magnetic line is consistent to form a shortest closed magnetic wire circuit, so that the inner rotor will rotate in clockwise.

When the direction of the rotor magnetic field is perpendicular to the external magnetic field, the rotor torque is the largest. Note that the "torque" is the biggest, not the "force". It is true that when the rotor magnetic field is the same as the external magnetic field, the rotor is the most magnetic, but at this time, the rotor is in a horizontal state, and the force arm is 0, of course, it will not rotate. In addition, the torque is the product of force and force. One of them is zero, and the product is zero.

When the rotor turns to the horizontal position, although it is no longer the effect of rotating torque, due to inertia, it will continue to rotate clockwise. Turn forward.

State 2

In this way, the current direction of the two screw wire tube is constantly changing, and the inner rotor will constantly turn. This action that changes the direction of the current is called a change. Supplement: When the change is only related to the position of the rotor, it is not directly related to any other amount.

Part 2: Three -phase diode internal rotor motor

Generally speaking, the three -phase winding of the stator has a star -shaped connection method and the triangular connection method, and the "three -phase star connection two -two guide" is the most commonly used. Here is a simple analysis.

The figure above shows the connection method of the stator winding (the rotor is not drawn as a diode magnet), and the three windings are connected together by the "Y" type through the connection point of the center. The entire motor leads three lines A, B, C. When they are two or two between them, there are 6 cases, namely AB, AC, BC, BA, CA, CB Note that this is orderly.

Below I look at the first stage: AB is connected to

When the AB is powered on, the magnetic line direction of the A polar coil is shown in the direction of the red arrow, and the direction of the magnetic line generated by the B pole is shown in the blue arrow. Assuming that there is a diode magnet, according to the "in the middle of the rotor will keep the direction of the magnetic sensing line inside with the direction of the external magnetic induction line\\ As for C, there is nothing for him for the time being.

The second stage: AC phase power

Third stage: BC phase power

Fourth stage: BA phase power

Each process rotation 60 degrees

The six processes completed a complete rotation, of which 6 were changed.

The third part: three -phase multi -winding multi -polar internal rotor motor

Let's take a look at a complicated point. Figure (a) is a three -phase nine winding six -pole (three -pair pole) internal rotor motor. Its winding connection method is shown in Figure (b). It can be seen from Figure (b) that its three -phase winding is also connected together at the middle point, and also belongs to the star form connection. Generally speaking, the number of windows of the motor is inconsistent with the number of permanent magnet poles (such as the 9 winding 6 pole instead of the 6 winding six poles), which is to prevent the teeth of the stator from being aligned with the magnetic steel of the rotor.

The principle of its movement is that the N pole of the rotor has a motion trend of alignment with the S of the power -powered winding, and the S extremely aligned with the N pole of the rotor with the N extremely alignment.

That is, S and N are attracted to each other, paying attention to the difference from the previous analysis methods.

Okay, let's analyze it again,

The first stage: AB phase power

The second stage: AC phase power

Third stage: BC phase power

Fourth stage: BA to power

Fifth stage: CA to power

Sixth stage: CB to power

The above are six different power -powered states, including five rotation processes. Each process is 20 degrees.

Part 4: Outer Rotorless Brushless DC motor

After watching the structure of the inner rotor -free DC motor, let's look at the external rotor. The difference is that the external rotor motor made the magnetic steel that was originally in the center position into a piece, and pasted it on the shell. When the motor was running, the entire shell was rotated, and the middle coil stator remained motionless. Compared with the inner rotor, the rotor of the rotor is much larger than the inner rotor (because the main quality of the rotor is concentrated on the shell), so the speed is slower than the inner rotor motor. Usually the KV value is hundreds to thousands of thousands of thousands between. It is also the main use of the brushless motor used by the aerial model

By the way. The KV value of the brushless motor is defined as: the speed/V, which means that each voltage increases at a speed of speed, the speed value of the brushless motor is increased. For example, an outer rotor -free motor with a nominal value of 1000kV. Under the voltage conditions of 11 volts, the maximum air load speed is: 11000rpm (the meaning of RPM is: turn/minute).

The brushless motor of the same series and the size of the shape, according to the number of winding turns, will show different KV characteristics. The number of winding turns is large, the KV value is low, the maximum output current is small, and the torque is large; the number of winding turns is small, the KV value is high, the highest output current is large, and the torque is small. I have previously tested the extreme current of crossing the 2204 motor. The single motor function can be on the 25A, while the 2212 series motor 15A cannot be available.

The structure of an outer rotor -free DC motor:

The analysis method is similar to the inner rotor motor. You can analyze it yourself. According to the right hand spiral theorem, the N/S pole of the coil is determined by the coil. The S pole has a trend of alignment (attraction) in Nary Winding N, thereby driving the motor to rotate.

Analysis of classic brushless motor 22121000KV motor structure.

The picture shows the DJI2312S motor and XXD2212 motor (anatomical drawing)

The structure is as follows: The stator winding is fixed on the base, the rotation shaft and the shell are fixed together to form a rotor, and the bearing in the middle of the stator is inserted.

The picture shows XXD2212 coil disassembly diagram

The picture shows the 12 winding 14 pole (that is, 7 pairs), and the motor winding winding diagram.

There are 6 kinds of two -phase power -on situations. It can be seen that although there are many changes in the number of winding and magnetic poles, from the perspective of electrical control, the order of power is actually the same, that is, regardless of whether it is, regardless of whether The external rotor is also an internal rotor motor, which follows the order of AB-\\u003e AC-\\u003e BC-\\u003e BA-\\u003e CA-\\u003e CB for power transformation.

Of course, if you want to make the motor reverse, the electronic method is to power in the upside-down order; the physical method is directly to the two lines to adjust the two lines. \\u003e CB-\\u003e CA, have you found that the order here is completely upside down.

AB phase power

AC phase power

BC phase power

BA phase power

CA phase power

CB phase power

It should be explained that because each of which leads to two winding at the same time, the current is divided into two roads. In order to make the problem as simpler as possible, only the main current direction of the road is drawn in the following figures, and the current of the current is not drawn. Essence

4. Professional term in a brushless motor

The rated voltage:That is, the working voltage suitable for the brushless motor. In fact, the working voltage suitable for the brushless motor is very wide. The rated voltage is obtained from the specified load conditions. For example, the 2212-850kV motor specifies the load of 1045 propeller, and its rated operating voltage is 11V. If the load is reduced, such as a 7040 propeller, then the motor can work under 22V voltage. However, this working voltage is not infinitely rising, mainly due to the highest frequency supported by electronic controller. Therefore, the rated work is determined by the working environment.

KV value:There are brushing motors marked the rated speed based on the rated operating voltage. The concept of KV value -free motor introduces the KV value, so that users can intuitively know the specific speed of the brush -free motor under specific working voltage. The actual speed \\u003d KV value*working voltage, this is the actual significance of the KV, that is, the speed per minute per minute under 1V working voltage. The speed of the brushless DC motor is proportional to the voltage, and the speed of the motor will rise linearly with the voltage increase. For example, the speed of the 2212-850kV motor at 10V voltage is: 850*10 \\u003d 8500rpm (RPM, speed per minute).

Torque:(Torque, torque) The driving force that can be used to drive the mechanical load can be used by the motor. We can understand the power of the motor.

Rotating speed:The speed of the motor is generally represented by RPM.

Maximum current:The maximum current that the motor can withstand and work safely

Maximum power: The maximum power power of the motor can withstand and work safely \\u003d voltage*current

Power and efficiency of brushless motor:

We can simply understand the power output power \\u003d speed*torque. At the same power, the torque and speed are a long relationship, that is, the higher the speed of the same motor, the lower its torque. On the contrary Also. It is impossible to require the speed of the motor to have higher speed and higher torque. This law is common to all motors. For example: 2212-850KV motor, 1045 paddle can be driven in the case of 11V. If the voltage doubles, the speed of its speed is doubled. If the load is still 1045 paddles at this time, the motor will soon be due to current and temperature due to current and temperature The sharp rise and burned.

Each motor has its own power limit, and the maximum power is this upper limit. If the working situation exceeds this maximum power, it will cause the motor to burn at high temperature. Of course, this maximum power also specifies the work voltage. If it is higher at a higher working voltage, the reasonable maximum power will also be improved. This is because: Q \\u003d I2R. The heating of the conductor and the square of the current is a positive relationship. At a higher voltage, if it is the same power, the current will decrease and reduce the heating, which increases the maximum power. This also explains why a large number of 22.2V or even 30V batteries is used on professional aerial aircraft to drive the multi -axis aircraft. The brushless motor under high voltage has a small current, small heating, and higher efficiency.

Some people often ask: What are the differences between 2208 1000kv and 2216 1000KV. They are all 1000KV, isn't it the same? Oh, the difference is large.

With the same diameter and KV values, the higher the natural power of the motor, the larger the motor, and the greater the power of the motor that can be driven. It's like a man 100 pounds and a man 160 pounds. You asked them to carry a bag of 50 pounds of rice. Although 100 pounds of men said that they were slightly strenuous, they could also carry them. 160 catties men felt that it was a side dish. But, if it was for them to carry two bags of rice? 160 pounds of men gritted their teeth, and 100 pounds of men may not be straightforward. This is their difference. For the motor, the easier the work, the higher the efficiency. The previous theory is that the iron consumption is also low.

Remember this formula (focusing): the square proportional to the square of torque is proportional to

As the motor work is getting tired, its efficiency will be reduced rapidly. Therefore, choosing a multi-axis motor must choose the appropriate power motor and the propeller that is matched with him to make the motor work in a relatively easy state. Generally speaking, the working power is better between 30-45%of the maximum power. Do not pull the big car, nor can you pull the trolley.

The relationship between the voltage and efficiency of the brushless engine:

First two formulas:

1. Power \\u003d voltage*current

2. Send heat \\u003d square of current*resistance

From the formula, two conclusions are concluded: the higher the voltage, the smaller the voltage at the same power, and it is launched: the higher the voltage, the smaller the calories. Finally, the conclusion: The higher the voltage used, the smaller the current, the less the current and the less heat, and the higher the efficiency.

Now I know why the high -voltage wire is 100kV or even 220kV, 550kV (this KV is KV), right?

Of course, the aircraft needs to be driven by the battery. To be precise, the lithium battery. The number of lithium batteries naturally depends on the size of the battery. The larger the battery can naturally do the voltage. So in terms of voltage, in fact, we can do not do much, because many batteries on the market are series, such as 450 models, you can find a 6S battery of 450 helicopter, but the price is very high. And the electrical price price is higher. Therefore, what we should do in terms of voltage is to avoid using low -voltage batteries as much as possible, which will cause relatively high working currents, which will consume large copper. At the same time, it is necessary to avoid high -pressure batteries for small aircraft, so the weight of the battery is too large.

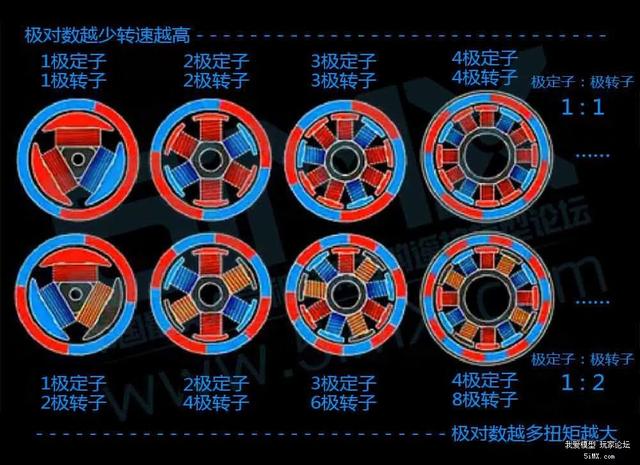

About the magnetic pole pair of the brushless motor

The rotation speed of the magnetic field is also called synchronous speed, which is related to the frequency of three -phase current and the magnet polar Pyrant P. If the Dingzi Winding, there is only one pair of magnetic poles that synthesize the magnetic field at any moment (magnet pole pair P \\u003d 1), that is, there are only two magnetic poles. For the rotating magnetic field with only one pair of magnetic poles, the three -phase current changes for one week, and the synthesis magnetic field will follow. For a week of rotation, if it is a 50Hz AC power, the synchronous speed of the rotating magnetic field is 50 rpm/second or 3000 rpm. In engineering technology, the rotation/point (R/min) is often used to indicate the speed. If there are two pairs of magnetic poles (magnet pairing p \\u003d 2) of the magnetic field formed by the stator around the combination, that is, there are four magnetic poles, which can prove that the current changes in one cycle and the synthetic magnetic field rotates 180 degrees in the space. The synchronous speed of the magnetic pole rotation magnetic field is n \\u003d 60F/P.

When the magnetic pole is confronted to a certain amount, if the frequency of AC power is changed, the synchronous speed of the rotation magnetic field can be changed. This is the basic principle of frequency conversion speed regulation. Because the magnetic pole of the motor appears in pairs, it is often expressed by the pole pairs.

About a brushless motor magnet

The brushless motor in the model industry is almost 100%"magnetic king" -corbone boron magnet, which is used to describe the magnetic king to describe the 钕 iron boron magnets well. 3 times the magnetic magnetic! Of course, the price is more than 10 times the iron oxygen magnet. The brushless engine belongs to the permanent magnet motor, and the power and characteristics of the permanent magnet motor depends on the magnetic. Basically, the volume of the magnet and the brand of the magnet determine the maximum power of the motor.

In addition, there is a difference in the shape of the magnet. If you disassemble some cheap motors, you will find that most of the magnetic shapes are square. The square -shaped magnet is simple and the price is relatively cheap, which naturally becomes the best choice to pursue a cost motor. Many brand motors have chosen curved magnets. The arc can ensure that the air gap between magnets and silicon steel sheets has been consistent. It seems that the power and efficiency are better than the square magnet. However, when some motors were dismantled, they also found the magnets called bread -type. They could be fully fit with the iron shell, but the distance from the silicon steel sheet was the same as the square magnet, which was not consistent. Regarding this magnet, some people in the industry are consulted. They are convinced that this magnetic effect is better than the curved magnet.

However, there is another case that uses square magnets. It is actually possible. In the multi -slot, the number of brushless motors (such as the 36 slot 42 polar motor) basically uses a square magnet. The square magnet can also be well bonded with the iron shell, and the air gap with the silicon steel sheet is also very uniform.

Silicon steel sheet of brushless motor

In fact, when reading electromagnetics in junior high school, the question I often think is why the motor needs silicon steel sheets? Isn't it that the conductive conductor can produce effects in the magnetic field? Then why do I still need silicon steel sheets. Later, I thought about it for a long time and finally got a conclusion, that is, people who are designed will not be stupid than you!

The air is weak magnetic, but iron is magnetic. The role of silicon steel sheet is to guide the magnetic circuit of the magnet and form a circuit. This requires the motor magnetic resistance (everyone understands it as a resistance). But everyone saw it, why is the stator composition one by one?

Do you know the principle of the induction cooker? Why does the iron pot fever on the induction cooker? In fact, this is because of the material similar to the iron in the rapidly changing electromagnetic field (everyone thinks about AC electricity, that electric is an instant instantaneous Flying and flying, unlike DC electricity is always positive to negative), it will generate vortex losses and fever, and the higher the frequency, the greater the heat. The silicon steel sheet is in the rotating magnetic field of the motor, which is the same problem as the iron pot placed on the induction cooker. The solution is to add silicon to the steel and make a thin piece. The smaller the loss.

So do you understand that the ordinary fixed -wing motor is mostly a thicker 0.35mm silicon steel sheet, and most of the helicopter and the culvert motor are used for 0.2mm silicon steel sheets? The faster the motor speed, the faster the magnetic field changes. Then The greater the vortex loss. Most multi -axis motors now use 0.2mm single -piece silicon steel sheet, and the iron consumption of the motor will be lower.

Related small knowledge: Why does the high -KV motor be hot when the full throttle is vacated?

the answer is:It is not a copper line that generates heat, because the current passed at this time is small. It is the vortex loss and stagnation loss that generates heat, because at this time the motor is completely empty, the speed is relatively high, the vortex loss is large, and all the loss finally becomes calories.

About the use and maintenance of brushless motors

The DC brushless motor consists of the main body and the driver of the motor and the driver. It is a typical mechanical and electrical integrated product and is widely used in multiple fields. There are some problems when using a DC brushless motor to pay attention.So what should I pay attention to when using DC brushless motors?

(1) Before disassembling, use compressed air to blow the surface dust on the surface of the motor and wipe the surface dirt clean.

(2) Select the work location of the disintegration of the motor and clean up the on -site environment.

(3) Familiar with the characteristics of motor structure and maintenance technical requirements.

(4) Prepare tools (including special tools) and equipment for disintegration.

(5) In order to further understand the defects in the operation of the motor, a test can be performed before disassembly. For this reason, the motor is brought with a load to test, check the temperature, sound, vibration, etc. of each part of the motor, and test the voltage, current, speed, etc., and then disconnect the load. Delivery and vacuum loss, record records.

(6) Cut off the power, remove the external wiring of the motor, and make a record.

(7) Select the insulation resistance of the motor of the MSU table with the appropriate voltage. In order to compare the insulation resistance value measured during the last maintenance to judge the changing trend and insulation state of the motor, the insulation resistance value measured at different temperatures should be converted to the same temperature, and it is generally converted to 75 ° C.

(8) Test absorption ratio K. When the absorption ratio is greater than 1.33, it indicates that the motor is not tide or the degree of moisture is not serious. In order to compare with previous data, the absorption ratio measured at any temperature should be converted to the same temperature.

Article Source: Reprinted from the bread board community