1. 1. Background

On November 220, 2020, the General Office of the State Council issued the "New Energy Vehicle Industry Development Plan (2021-2035)" (hereinafter referred to as "20 -year version plan"). It dropped to 12.0 kWh/100 kilometers, and the sales volume of new energy vehicles reached about 20%of the total sales of new cars. Highly autonomous vehicles realized the commercialization of limited areas and specific scenarios. By 2035, pure electric vehicles will become the mainstream of new sales vehicles, comprehensive electrification of vehicles in the public domain, commercial application of fuel cell vehicles, large -scale autonomous vehicles to achieve large -scale applications, effectively promote energy conservation and emission reduction levels and social operation efficiency promote.

The 20 -year version of the plan has been deployed one of the five strategic tasks. It adheres to the equal emphasis on the entire vehicle and components, strengthens the integration technology innovation of the vehicle, enhances the industrial basic capabilities of key components such as power batteries and new -generation vehicle motors, and promotes electrification and network Coordinated development of joint and intelligent technology.

In October 2020, the China Automobile Engineering Society released the "Power Conservation and New Energy Vehicle Technology Road Figure 2.0" in Shanghai (hereinafter referred to as: "Road Figure 2.0"). The sales volume of energy -saving and new energy vehicles in 2035 reached 50%, 2035 2035 The sales of new vehicles in the Chinese automobile market reached 30 million units, and the sales volume of energy -saving and new energy vehicles is expected to reach 15 million units. "Road Chart 2.0" focuses on 9 technical directions, including power batteries, electric drive systems, charging infrastructure, energy -saving vehicles, pure electric and plug -in hybrid cars, fuel cell vehicles, intelligent connected cars, lightweight, intelligent, intelligent, intelligent, intelligent, intelligent, intelligent, intelligent Manufacturing and key equipment.

The above State Council's "20 Years Plan" and the "Road Chart 2.0" of the Chinese Automobile Engineering Society mentioned "new generation of vehicle motors" and "electric drive system". This shows that it is necessary to develop new energy vehicles, and the status of vehicle motors and systems is very important. The following interpretation of the "Development Plan for the Development of the New Generation of the Motor Motor Technology".

2. "20 Years Plan" 2 key technical indicators

-

By 2025, the average fuel consumption of passenger cars will be required to reach 2L of 2L. The current situation is that the average fuel consumption of passenger vehicles is 5L per 100 kilometers. (Note: From 5L to 2L, what technology can you use to achieve this indicator?)

-

By 2035, new energy vehicles will account for more than 50%of the total vehicle sales, of which pure electric will account for more than 95%of new energy vehicles.

(Note: The sales volume of the Chinese automobile market in 2035 reached 30 million units, and the sales volume of energy -saving and new energy vehicles is expected to reach 15 million units. It is broken down into pure electric vehicles: 1.425 million units, including 1 million hydrogen vehicles, which can be understood. (Including B -Class) Passenger cars must basically be pure electric vehicles.

At the end of 2020, the sales of energy -saving and new energy vehicles were only 1.26 million, and it would be increased to 15 million units in 10 years. How high is the steps of each year? )

Third, car motor technology bottleneck

① The bearing of the motor of the speed of 16000 (R/min) or above is basically imported;

② Electromechanical coupling assemblies in the field of hybrid and plug -in fields, the core technology is basically monopoly by foreign companies;

③ The four -wheel wheels/wheel edge electric assembly is still in the technical research stage, which is far from the commercialization of the product;

④ Distributed -driven electric chassis project research, the national 14th Five -Year science and technology planning has just been laid out.

4. The main technical points of the electric drive system

1. High power density of the electric drive system

1) High power density:

Output greater power at a certain volume, in order to achieve this goal, there are generally two ways:

① According to (p/v) \\u003d kn, when the volume is unchanged, the power output power is proportional to the speed. Improve the speed of the motor, that is, design the motor into a high -speed motor,

② When it is not suitable for increasing the speed of the motor, optimize the design of a new structure motor to fundamentally solve the power output power of the same motor.

2) Torque and thrust density: Output large torque (rotating motor) or thrust (linear motor) at a certain volume. This motor is generally low, and the total output power is not necessarily large.

2. Electric drive system high efficiency

The efficiency of the electrical drive system is the most closely related technical indicator with the mileage. At present, there are two aspects to improve the efficiency of the electric drive system. One is hardware and the other is software.

In terms of hardware: It has the design solution of the power motor ontology, the improvement of the manufacturing process, and the use of new materials. The core technology is to start with the inverter's hardware and use the power module with lower loss. The main IGBT is currently used, and the next SIC.

Software aspect: control algorithm optimization method.

3. Basic requirements for vehicle motors

High -power density electric drive motor, low -speed large torque motor, high -speed motor, large thrust line motor.

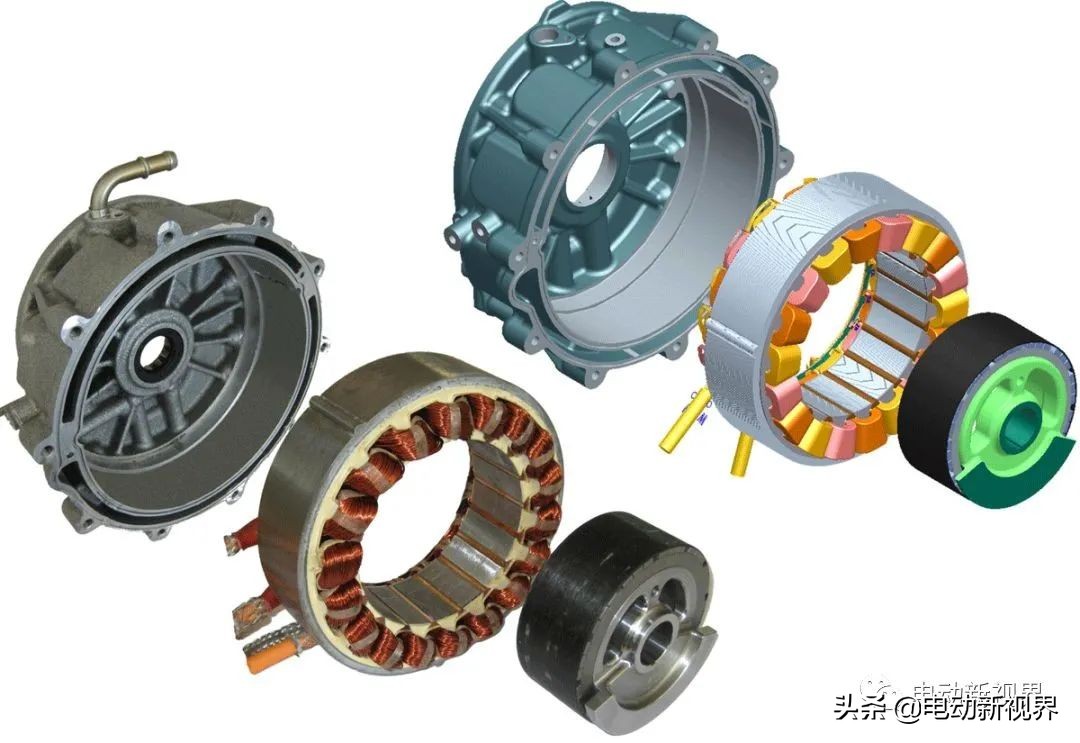

Fourth, the most typical vehicle driver motor is permanent magnet synchronous motor

With its absolute advantage of high torque density, high power density, high -efficiency, and high reliability, with its high torque density, high power density, high -efficiency, and high reliability, he has converged to the basic model of multiple models into a parallel development model.

For a long time in the future, the development of permanent magnet synchronous motor system as the main body is basically unchanged.

Fifth, motor drive wheel method

① Concentrated motor drive form

With only one drive motor, this form of motor is installed in the car body. The driving moment generated by the motor is passed to the driver wheel through differentials and transmission shafts. This model will eliminate the transmission.

② Wheel motor driver form

The motor is installed on the driver wheel, and the driver wheel is directly driven by their respective motors. The layout of the wheel motor drive system is very flexible. It can be arranged in the two front wheels, two rear wheels or all wheels of the electric vehicle, making electric vehicles a front wheel drive, rear wheel drive or multi -wheel drive vehicle.

The form of wheel motor is the future development trend. The development of wheel motors driving will eliminate the transmission shaft and differential.

6. The main gap between my country's electric drive system

From the perspective of the architecture of the electric drive technology chain, ① The power assembly is divided into pure electric assembly; ② electromechanical coupling power assembly; ③ wheel/wheel edge electric assembly.

The main gap between my country's electrical drive system and foreign countries is in the depth of the vehicle, especially in the electromechanical coupling assemblies in the hybrid and plug -in fields. In addition, key parts and materials, especially high -speed bearings, are the shortcomings of domestic enterprises.

The development of intelligent connected cars requires autonomous vehicles to be distributed, which is the wheel motor of the four -wheel wheels.

7. The advantages of my country's electric driver industry

Since 2001, China Electric Driven has made great progress in my country's new energy vehicle technology and industries after four "five -year plans". At present, the motor power has covered thousands of watts to hundreds of kilowatts. At present, China's new energy vehicle motor and electronic control local enterprises are more than 80%, and the complete industrial chain of vehicle and core components to basic materials has been formed. Has been greatly improved. More importantly, breakthroughs in some core components. At present, new energy vehicles of independent brands can already compete with international brands on the same platform. From car companies' own research and development capabilities, to the research and development institutions in the society Assure.

8. The development trend of the core technology of my country's electric driver

① The driving motor speed is increased to 16000-18000 (R/min), and then increases to 20000 (R/min) to strive to reach the speed of 300,000 (R/min);

② The inverter will increasingly use SIC devices. SIC devices high temperature, efficient, and high -frequency characteristics are the key to the continuous improvement of the power density and efficiency characteristics of the motor controller. Toyota is equipped with SIC PCU by 30%compared with the IGBT PCU loss. Tesla uses a standard SIC device parallel to connect. The large -current all -current full SIC motor controller developed by it has taken the lead in industrialization.

Some companies abroad have adopted GAN devices;

③ The motor winding structure, the soft group and the flat wire winding of the hair card have clearly become the technological development direction.

④ The technology of high -performance silicon steel sheets. Copper wire technology with better conductivity and internal resistance is also the direction of technological progress;

⑤ The three -in -one motor controller has become the mainstream, and its advantages are very obvious, which not only saves costs, but also improves performance and efficiency. In the future, there will be more in -depth integrated products of five -in -one, seven -in -one, and Bayi, and Bayi.

Nine, the author's suggestion

① The bus systems of large cities in China have basically completed electrification. Pure electric is no problem in the specific scenario of the bus system. At present, many places are actively promoting the promotion of hydrogen energy buses, but do not use hydrogen buses to replace pure electric buses.

② Specific commercial vehicles have the advantages of marketization with hybrid power, mainly to make up for the scene where pure electric technology cannot be deepened. Mainly thinking, subject to restrictions on endurance mileage and charging time.

③ The distributed driver's wheel motor application can be thought about starting from the autonomous driving of low -speed vehicles.

④ Drive motor specifications are more specified and widely used. There will be no unique situation, but the industry needs to work together.

Article Source: Reprinted from the new perspective of electric